Melt flow index tester

Melt flow index tester introduction

A. Structure and working principle:

Melt flow index tester is an extruded plastic testing instrument. The inner high temperature melting furnace is used to make the measured object reaching the molten state successfully at the predetermined temperature condition. Then the measured object in the molten state goes through a certain diameter at the gravity of the specified weight load to operate the extrusion test. Melt(mass) flow rate is often used to represent the fluidity, viscosity and other physical properties of the polymer material in the molten state in the industrial plastic production and scientific research .The melt flow index refers to the average weight of all sample sections translated to the extrusion rate of 10 minutes.

Melt(mass) flow rate is represented by MFR, unit:10min/g Formula:MFR(θ、mnom )

=tref .m/t

: θ—— test temperature mnom— nominal load /Kg

m —— average cut mass /g

tref —— reference time(10min), S ( 600s ) t —— cut time interval /s

eg.:A set of plastic samples were cut down every 30 seconds.

There are five segments ,the quality of the results are as follows: 0.0816g,0.0862g,0.0815g,0.0895g and 0.0825g.

The average vale M

=(0.0816+0.0862+0.0815+0.0895+0.0825)÷5=0.0843(g)

Substituting into the formula: MFR=600×0.0843/30=1.686(g/10min)

The melt flow index tester consists of furnace and temperature control system and the furnace and temperature control system are all installed in the fuselage (column)of the base.

The thermostat temperature control part uses SCM to control the power. The anti-interference ability,high temperature precision and stable control of the control system well meets the demand of the standard. In addition, the furnace heating wire wrapped around the heating rods according to certain rules so that the temperature gradient is the minimum to meet the standard requirements.

B. Usage of keyboard:

1、Keyboard structure and functions

The instrument keyboard is composed of “0-9” 10 numeric keys, function keys and “↑ ↓” symbol function keys. Users can use them to enter the digital number.

3、 Functions of the keyboards

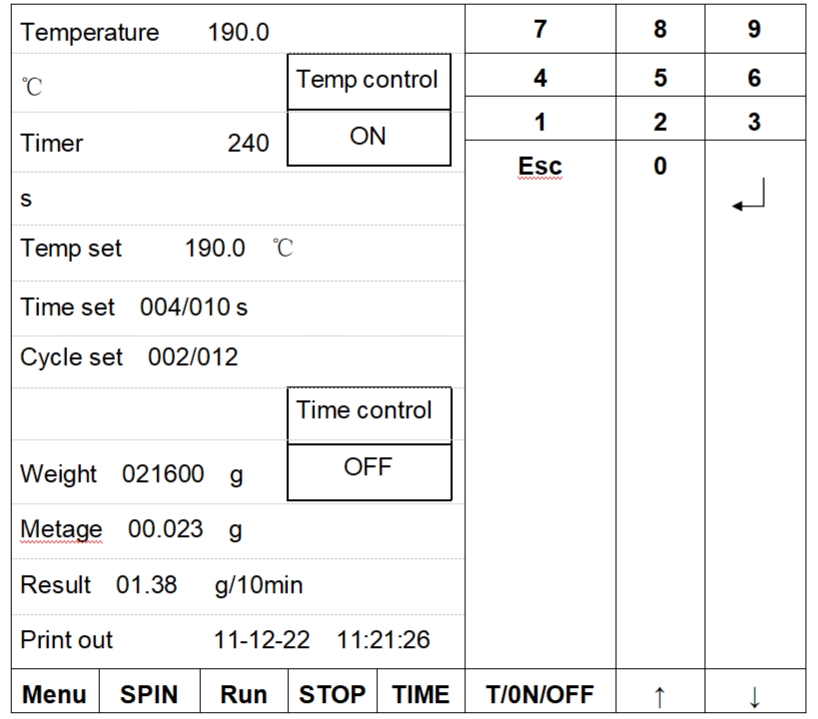

Graph 1:Panel Keyboard illustration:

“0~9” numeric keys are used to enter the digital number. Esc:it is used to cancel the error of the numeric input.

![]() :it is used to determine the input and select options.

:it is used to determine the input and select options.

Menu : The menu button is used as a select function key in the operation system. Before selecting any function, users must first select a menu and then use the direction keys to select the functions they need.

SPIN: If users press the manual cutting key in the main display

interface, the scraper will automatically run a rotation.

Run:The operation button is used to make the setting program run automatically.

Time:It is used to set the countdown heating test time

Stop:The stop button is used to stop the countdown process or the program running process.

T/on/off:The temperature control button is used to turn on/off the

temperature control. It can be open for heating and constant temperature control. If it is closed, the function will be unavailable. Main display interface description:

Temperature:Current actual temperature will be displayed here. In

the testing process, the running temperature is required to be within the range of 0.5℃ of the desired temperature.

Timer:When the Timing button is pressed, the 240s countdown will start.

Temp set:It is used to set the desired temperature.

Time set:004/010 s It means in the testing process, this has been a time 4s, the cutter rotates once every 10s automatically.

Cycle set: 002/012 times It means in the program running process, the cutter has cut two times of the total 12 cutting times.

Weight: It is used to enter the weight of the counterweight needed, making it possible when printing for statistics storage.

Metage:It is used to input the average weight of the small piece of

testing material which has been cut off.

Result:The results of the current melt flow rate will be calculated automatically.

Print out:Using the cursor to select and ensuring it, the conditions

and results of the test can be printed out automatically.

Temp control: There are two kinds of temperature control situation

OFF/ON to show the temperature control system is open or closed.

Time control:OFF/ON is used to symbolized whether the program

is on the work.

|

Material |

Testing temperatureθ,℃ |

Weight mnom,kg |

|

PS |

200 |

5.00 |

|

PE |

190 |

2.16 |

|

PE |

190 |

0.325 |

|

PE |

190 |

21.60 |

|

PE |

190 |

5.00 |

|

PP |

230 |

2.16 |

|

ABS |

230 |

10.00 |

|

PS-1 |

200 |

5.00 |

|

E/VAC |

150 |

2.16 |

|

E/VAC |

190 |

2.16 |

|

E/VAC |

125 |

0.325 |

|

SAN |

220 |

10.00 |

|

ASA、ACS、AEC |

220 |

10.00 |

|

PC |

300 |

1.2 |

|

PMMA |

230 |

3.8 |

|

PB |

190 |

2.16 |

|

PB |

190 |

10.00 |

|

POM |

190 |

2.16 |

|

MABS |

220 |

10.00 |

Latest News

Contact Us

Name: Anne Liang

Tel: +86-13592713824

E-mail: annelyno@163.com

WeChat: Annefa1156

Add: One building, 8 zhuzhong road, Houjie Town, Dongguan City

CHINESE

CHINESE ENGLISH

ENGLISH

Mail inquiry

Mail inquiry